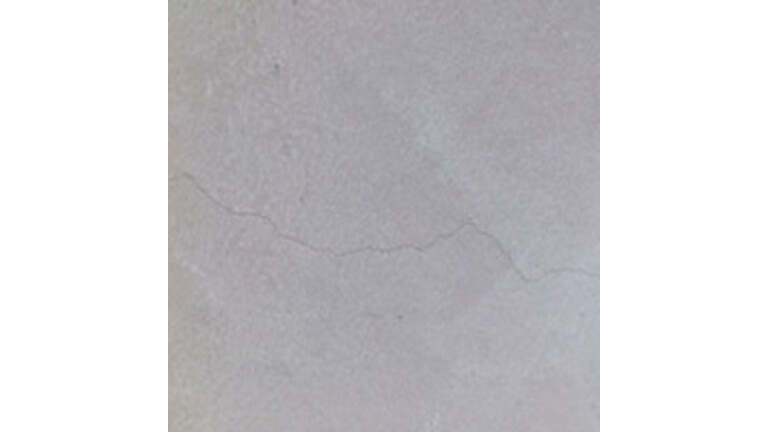

Plaster structural crack

Cementitious plasters are applied internally such as living rooms, bathrooms, kitchens, etc... And externally where they might be exposed to different environment conditions: sun light, wind…

Sodamco Weber offers a wide range of cementitious plaster that can be applied internally and externally and are suitable for different environment conditions depending on the available substrate.

Common issues and queries you can face

1-Reasons of plaster cracking or De-bonding

Many factors might affect the performance of an applied plaster.

Cracks in the plaster may result from cracks in the substrate causes of substrate failures:

- Thermal movement in the structure

- differential foundation movement. As per the standard BS EN 13914 "Render applied on backgrounds which may move are likely to crack, e.g. with movement of the structure, deflection of floor slab, high moisture of masonry"

- settlement, moisture expansion and drying shrinkage of masonry units

2-Reasons of plaster cracking or De-bonding

Structural cracks occur in the following directions:

- Horizontal cracks: expansion of wall ties, horizontal pressure.

- Vertical cracks: Pressure in the building structure, pressure around pipes.

- Racking cracks: Soil or foundation settlement, shear pressure.

Solution

Plaster structural crack repair

In case of structural cracks, the substrate is the element to be repaired.

- It is necessary according to EN 13914 the "Allowance of sufficient time between the construction background and the application of the rendering" in order to prevent any cracks due to drying shrinkage of masonry units or moisture expansion.

- Construction Engineers shall inspect the substrate for any damage or defect in order to take the necessary action for repairing before starting the plastering job. And to consider the load of the structure and the pressure around the openings before plastering.

-

Substrate preparation

- Sodamco Weber Cementitious render plaster can be applied directly over masonry blocks. Just dampen the substrate few hours before the application

- Smooth concrete surfaces, or those with low absorption, can be made more receptive to plaster application by first applying a spatter dash slurry coat (weber.premix SRC-2 or weber.premix SRC-S or weber.premix key coat) as a key coat for improved bonding and adhesion of subsequent layers.

-

Application of spatter dash slurry coat over concrete surfaces

- Mix weberpremix key coat or weberpremix SRC-2 or weberpremix SRC-S with the required quantities of clean water using an electric mixer to obtain the desired consistency

- Apply the spatter dash slurry coat with a tyrolean machine or a spraying gun, or by a traditional hand application.

- Cure the applied dash slurry coat after setting, for at least three consecutive days.

- For more application details follow the application method statement related to each case.

-

Plaster application

- Spray the plaster on the dampened and prepared surface, or apply it manually with a plastering trowel at a thickness between 10 to 20mm in one layer. For higher thicknesses, kindly consult the technical department.

- Follow the application method statement instructions

- Let the product set properly on the surface before any curing

- Curing with water for three days, three times a day.

- Protect the applied plaster from direct sun light and wind.